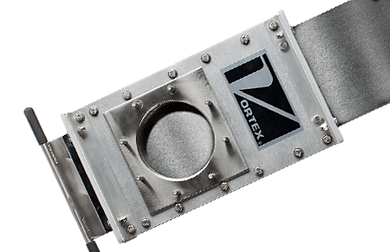

Slide Gates

Process Solutions is a Distributor of Vortex Valves in North and South Carolina

Orifice Gate- Vortex's line of Orifice Gate valves are engineered to handle dry bulk solids in gravity flow, dilute phase, or vacuum conveying systems with pressures up to 15 psi (1 bar). Unlike butterfly valves and knife gates, Orifice gates are designed to handle dry bulk powders, pellets and granules without concerns for material build up or seal break down.

More information about options applicable to your specific needs is available here

Roller Gate-Vortex's Roller Gate Valve is the best choice for gravity and low pressure scenarios. It can be crafted to the customer's needs (including rectangular configurations). Seals can be live loaded during replacement, drastically saving downtime for maintenance.

More information about options applicable to your specific needs is available here

HDPV2 Gate- The best slide gate option on the market for high pressure (up to 75 psi) applications, the HDPV2 gate has many of the same features as Vortex's other slide gates including the rising blade design and servicability in line.

More information about options applicable to your specific needs is available here

TPV Slide Gate- Part of Vortex's Titan Series, a line of products designed for the toughest applications, the TPV Valve is optimal for use in pressures up to 100 psi and temperatures up to 660° F. Engineered to have minimal maintenance over the life of the valve and features a replaceable seat that can significantly increase the life of the valve.

More information about options applicable to your specific needs is available here

Custom build applications have been completed for the coal, steel, aluminum, and cement industries

TSG Slide Gate- Part of Vortex's Titan Series, the TSG gate is designed for gravity applications with heavily abrasive materials.

More information about options applicable to your specific needs is available here

Clear Action Gate- Designed to be used in gravity or pneumatic flow applications up to 15 psi. This gate was designed with bulk material applications in mind and features a square-edged blade clears material from the sealing surface on every cycle, allowing it to discharge below the valve. This innovation means that seals are not degraded as quickly, reducing maintenance time.

More information about options applicable to your specific needs is available here

Maintenance Gate- A hand-cranked gate that was designed to close in the event of needed maintenance downstream in your process. The blade is designed to cut through material in case of upset conditions.

More information about options applicable to your specific needs is available here

Hand Slide Gate- Designed for gravity applications, the Hand Slide Gate uses a self-cleaning stroke to prevent wear and tear on the seals and full flow oriface to maximize material movement.

More information about options applicable to your specific needs is available here

Aggregate Slide Gate- Part of Vortex's Titan Series, the Aggregate Slide Gate is made to withstand extremely abrasive materials. Several features including the narrow profile and custom sizing (including rectangular applications) make this product adaptable to existing installations.

More information about options applicable to your specific needs is available here

Quick Clean Orifice Gate- Designed for applications where frequent gate cleanings are necessary, this valve features a full-port opening and self-cleaning design and can be assembled in minutes without tools.

More information about options applicable to your specific needs is available here